Offset printing is the most commonly used method today and has many advantages over other forms of printing, especially when we need consistent and high image quality.

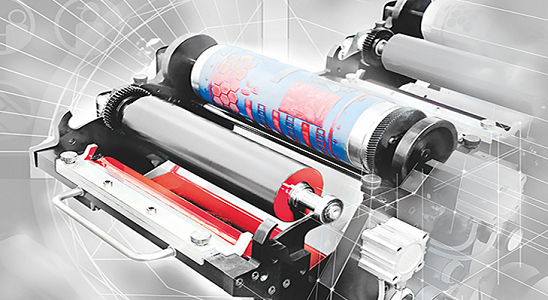

Offset printing is a printing technology in which an image is printed on a printing plate, on rubber, cylinders and then transferred to paper or other material. The rubber cylinder offers great flexibility and allows printing on wood, fabric, metal, leather and sandpaper.

The process of offset printing

The offset printing process consists of several parts

Implementation process

In this process, the ink is transferred from the ink fountain to the paper in several steps:

Advantages of offset printing

Another advantage of offset printing is the ability to adjust the amount of ink on the fountain roller with the screw keys. Most commonly, a metal blade controls how much ink is transferred from the ink chute to the fountain roller. By adjusting the screws, the distance between the blade and the fountain roller is changed, resulting in the amount of ink applied to the roller increases or decreases in certain areas. Therefore, the density of the color in the respective area of the image is modified. On older machines the screws are adjusted manually, but on modern machines the screw keys are electronically operated by the machine-controlled printer, allowing much more accurate results.

158/28/17 Phạm Văn Chiêu,Phường 9, Quận Gò Vấp, TP. HCM

Xưởng sản xuất: Số 10 Đường Nhị Bình, Xã Nhị Bình, Huyện Hóc Môn, TP. HCM

(+84-8) 625 77 602 - 0987 584 017

gialong.vn@vietnamexhibition.vn

www.vietnamexhibition.vn

Hotline